LGX Steel Drive Train Upgrade Set

$69.50 AUD inc GST

Out of stock

Push Harder! Full Steel Ahead!

Set of parts made of Hardened Steel to replace the plastic Drive and Main Double Gears on a Bondtech Large Gears eXtruder:

- LGX;

- LGX Lite;

- LGX Lite Mirrored.

Recommended to feed Engineering grade thermoplastics.

To use our LGX extruders above our default recommendations:

- with thicker mounting plates;

- at higher environment temperatures;

- at higher stepper motor currents.

Out of stock

Notify when stock available

Description

Lubrication is mandatory

These drive gears are made of hardened steel. Without lubrication they will wear your motor gear down.

Use a brush and the supplied lubricant to coat the drive gear teeth.

Metal gears conduct heat

To feed PLA or TPU (low Glass Transition Temperature materials)

keep the stepper motor cool (current at, or below, 0.5A).

The LGX extruders fit very well most filament extrusion applications, but some cases demand additional features or capacity that cannot be enabled by their plastic gear sets.

Those cases are:

1. When the LGX are used with a plate in between the extruder and the stepper motor thicker than our recommendation, and up to a limit.

On the LGX

Optimal Thickness : between 0.3 and 2.3 mm;

Limited to 3.0 mm

On the LGX Lite and LGX Lite Mirrored

Optimal Thickness : 2.5 mm;

Limited to 3.0 mm

2. When the LGX are used in work environments, warmer than our recommendation, and up to a limit.

On the LGX

We recommended Max Environment operating temperature : 70°C

Limited to 90°C

On the LGX Lite and LGX Lite Mirrored

We recommended Max Environment operating temperature : 70°C

Limited to 90°C

3. When the current fed to the LGX stepper motor is higher than our recommendation, and up to the 95% of the rated current.

On the LGX

Rated current: 0.7A.

We recommended between ~0.45 and ~0.60A

On the LGX Lite and LGX Lite Mirrored

Rated current: 1.0A.

We recommended between ~0.45 and ~0.60A

How To Install On LGX

INSTALLING THE LGX STEEL DRIVE TRAIN ON THE LGX

The guide below shows how to install the LGX Steel Drive Train on the LGX extruder.

The whole process is divided into 2 stages.

You will need a LGX extruder, the LGX hex key, and the LGX Steel Drive Train to perform this installation.

1/2 . Disassembling the LGX

Step 1. Remove Front Plate and Interface Plug

- Untighten this screw

- Untighten this screw

- Untighten this screw

- Untighten this screw

- Remove the interface plug and bottom screws

- Remove the front plate and top screws

Step 2. Remove the LGX Mid Section

- Remove the tube collet

- Remove the mid section with the pre-tension anterior lever. Be aware of the right hand side drive gear shaft coming along

- Next you will remove the drive gear/ drive wheels sets. Be aware of the shaft at the left hand side set

- Remove the drive gear/ drive wheels sets

- Remove the pre-tension posterior lever

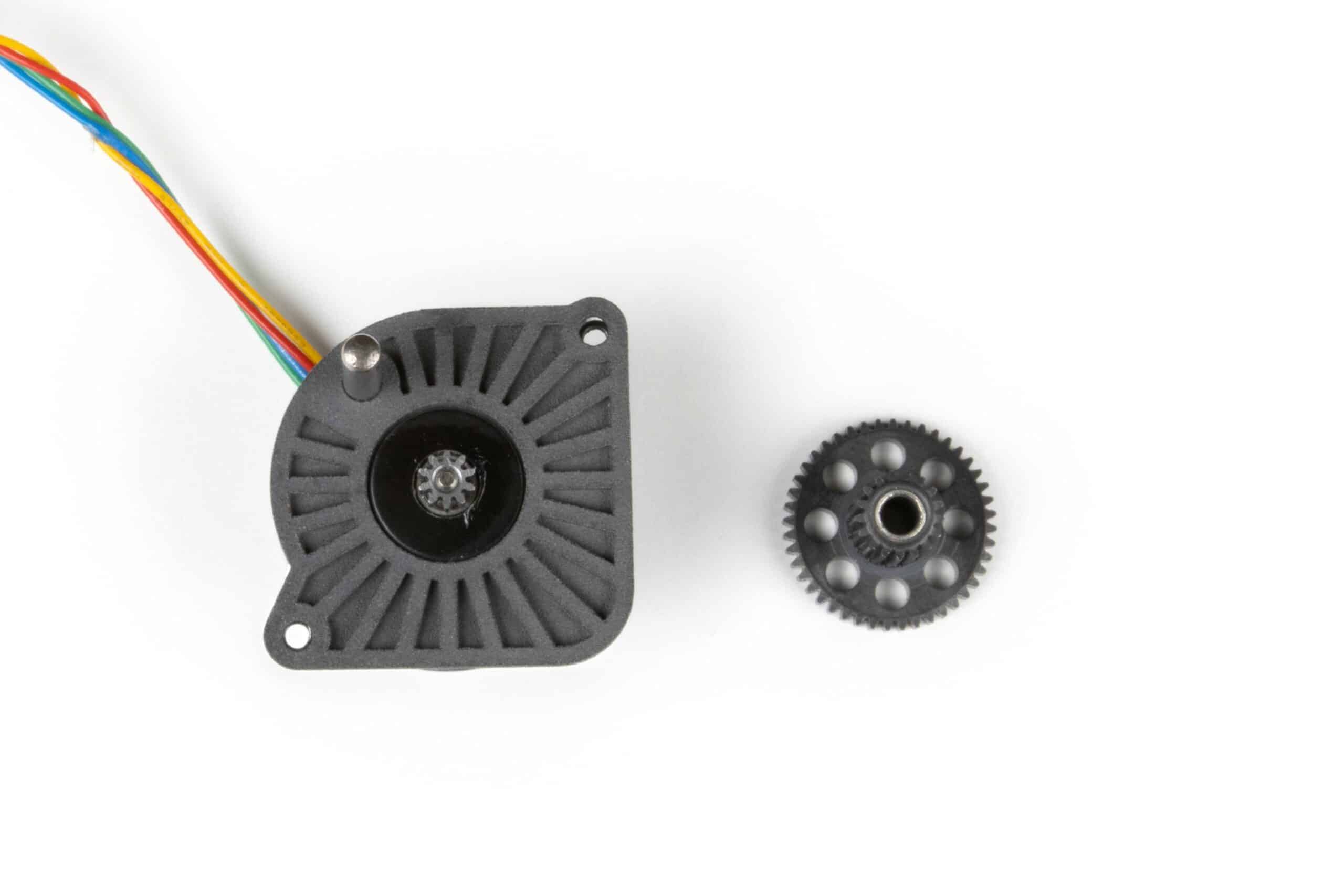

Step 3. Detach Stepper Motor, back plate and Main Double Gear

- Raise the back plate to decouple the main double gear from the motor gear

- Remove the main double gear and lock spring

- Remove the backplate from the stepper motor

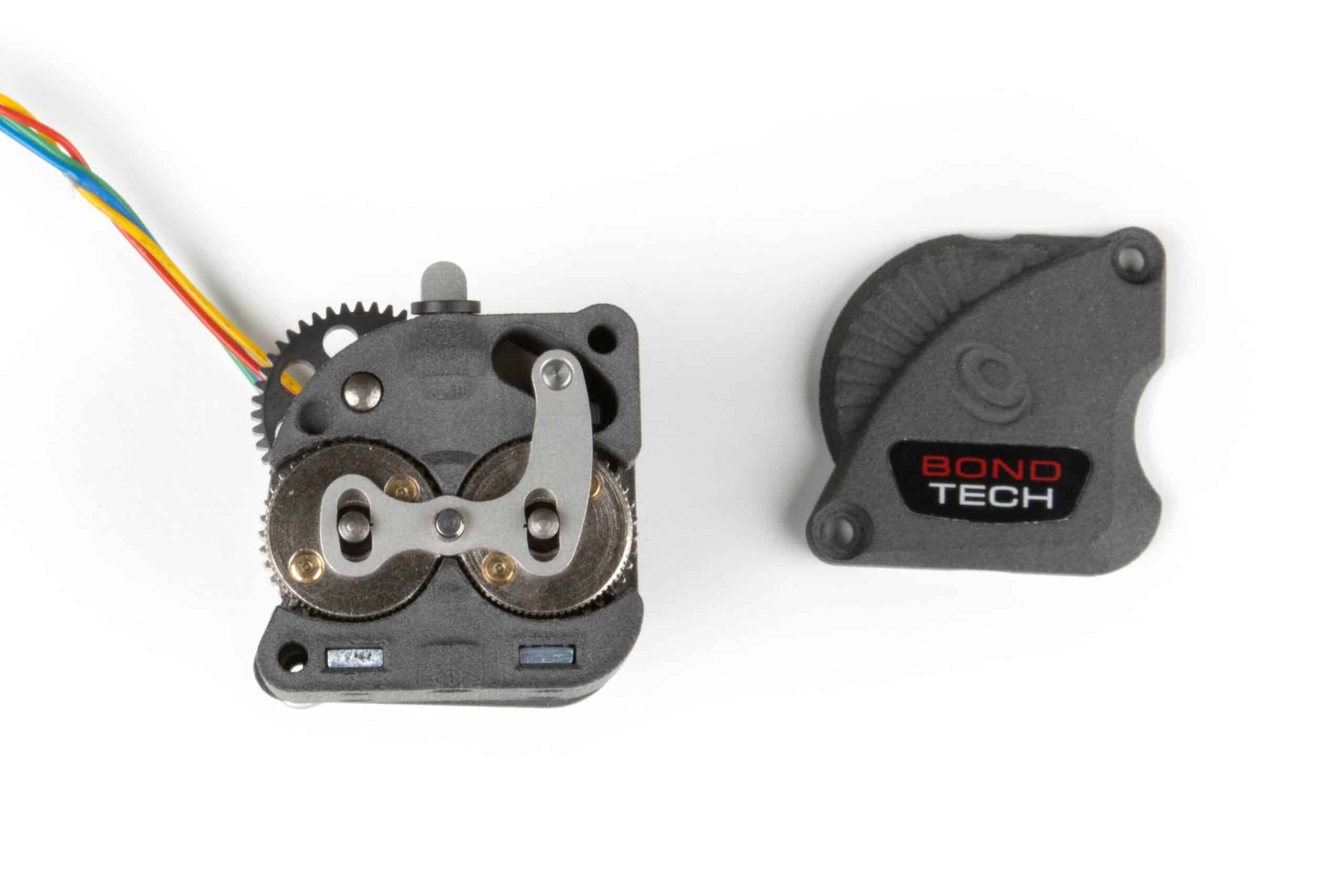

REPLACE THE PLASTIC DRIVE TRAIN WITH THE STEEL DRIVE TRAIN

Before continuing check you have all the items in these pictures. One missing part is enough not to be able to complete the procedure.

2/2 . Reassemble the LGX with the Steel Drive Train

Step 1. Prepare Back Plate and Main Double Gear

- Take the rear plate, the main double gear and the main double gear shaft (the thickest).

- Place the main double gear in the LGX rear plate.

- Place the main double gear shaft into the main double gear.

- This is the final shape of this step.

Step 2. Install Drive Gear Shafts and Posterior Pre-tension Lever Plate

- Add the posterior pre-tension lever and the 2 drive gear shafts.

- Place both drive gear shafts (thinner).

- Place the posterior pre-tension lever by aligning it with the previous placed shafts.

- This is the final shape of this step.

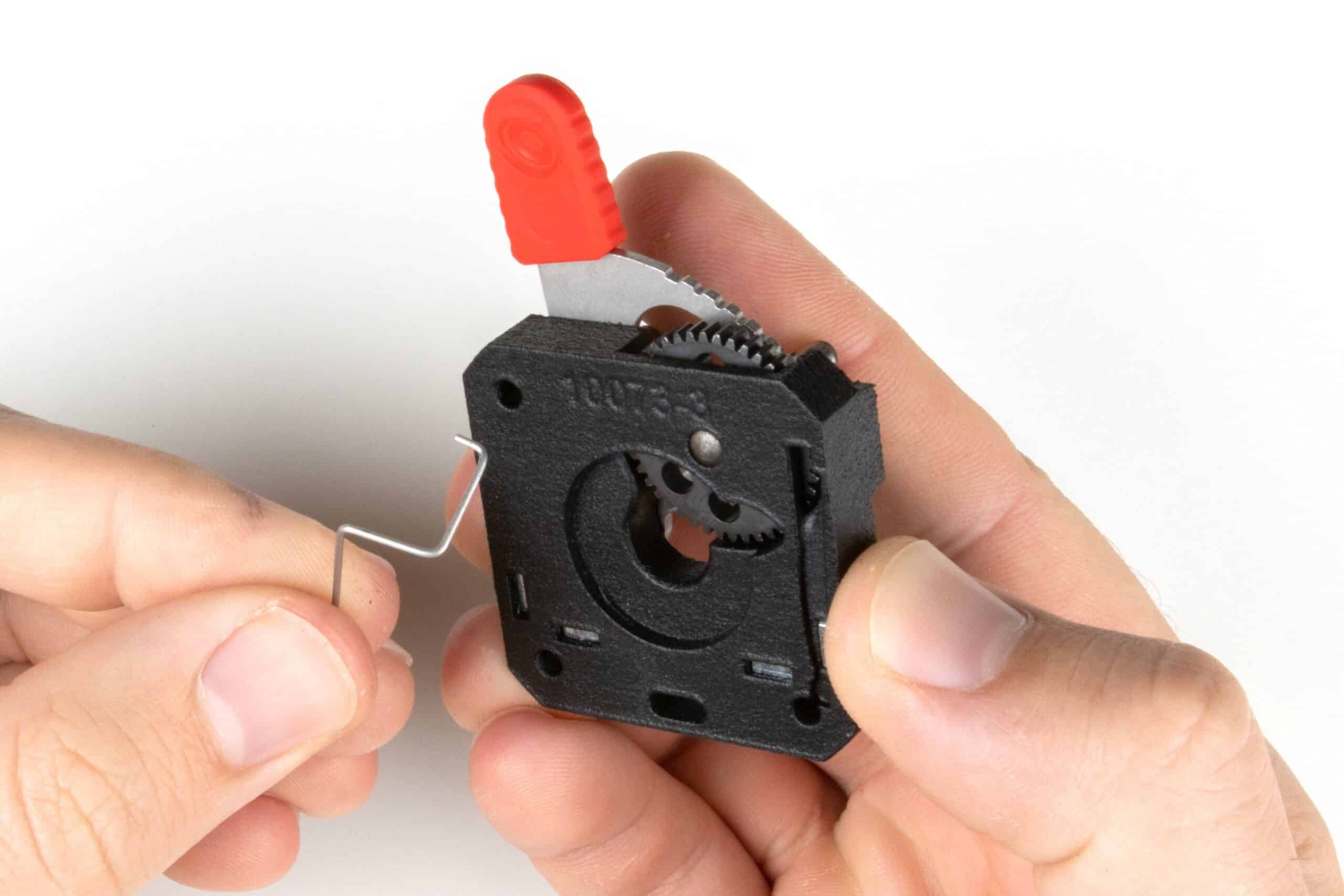

Step 3. Install the Pre-tension Lever Spring (do it slowly as here is where it’s harder)

- Add the pre-tension lever spring.

- You will have to reposition the pre-tension lever.

- Push the pre-tension lever to the right.

- Before continuing check the pre-tension lever is all the way to the right.

- Hold the spring on its longest straight section.

- Insert the short section through the back plate bypassing the main double gear.

- Twist the spring counterclockwise to go over the posterior pre-tension lever.

- Align the short spring section with the lever teeth.

- Move the lever arm to the left to engage a higher tooth. Hold the long section of the spring in tension.

- Move the lever arm to the left to engage a higher tooth. Hold the long section of the spring in tension.

- Twist it towards the top slot until it snaps and gets locked.

- This is the final shape of this step.

Step 4. Install the Drive Gears and Drive Wheels

- Add the 2 drive gear and drive wheels sets. They are both similar.

- Install one in the right hand shaft.

- Take the second set.

- Install it on the left hand side shaft. Twitch it a bit to align its teeth with the other drive gear and main dual gear.

Step 5. Install the Housing Mid Section

- Add the LGX housing mid section.

- Mind the orientation of the part.

- Align its holes with the shafts.

- This is the final shape of this step.

Step 6. Install the Anterior Pre-tension Lever plate

- Add the anterior pre-tension lever plate.

- Align the plate holes with the shafts.

- Align the plate pre-tension position indentations with the left hand side shaft and press it to fit.

- This is the final shape of this step.

Step 7. Install the Collet and reposition the Lever Arm

- Add the tube collet.

- Place the collet in place.

- Push the lever all the way to the left (position 0).

- This is the final shape of this step.

Step 8. Install the Front Plate

- Add the housing front plate.

- Drop it down aligning the top holes and the gap for the pre-tension lever.

- This is the final shape of this step.

Step 9. Install the Interface Plug

- Add the interface plug. In the picture we can see a Direct Extruder interface plug. The same can be done with the Bowden Extruder interface plug.

- Slide the interface plug into the LGX bottom slot.

- This is the final shape of this step.

Step 10. Install the Stepper Motor

- Add the LGX stepper motor.

- Align the LGX stepper motor with the LGX extruder.

- Wiggle both extruder and stepper motor to align the main dual gear and motor gear.

- This is the final shape of this step.

Step 11. Finish Assembling the LGX Extruder

- Add the LGX screws and hex-key.

- Place all the screws. The shorter one in the upper left corner.

- Tighten all the screws.

- This is the final shape of LGX extruder with the Steel Drive Train.

How To Install On LGX Lite

INSTALLING THE LGX STEEL DRIVE TRAIN ON THE LGX LITE

The guide below shows how to install the LGX Steel Drive Train on the LGX Lite extruder.

The whole process is divided into 2 stages.

You will need a LGX Lite extruder, the LGX hex key, and the LGX Steel Drive Train to perform this installation.

1/2 . Disassembling the LGX Lite

Step 1. Remove the Front Plate

- Untighten the 2 screws holding the LGX Lite and the stepper motor.

- Remove the 2 screws.

- And remove the front plate.

Step 2. Detach the Anterior Pre-tension Lever Plate

- Use the hex-key to lift the anterior plate from the shafts.

- Remove the anterior plate.

Step 3. Remove the Top Mid Housing and Drive Gears/Drive Wheels Shafts

- Remove the top mid housing.

- Remove a drive gear shaft.

- Remove the second drive gear shaft.

Step 4. Remove the Plastic Drive Gears/Drive Wheels Sets

- Remove the second plastic drive gear/drive wheel set.

- Remove the second plastic drive gear/drive wheel set.

- Remove the mid block including mid housing and posterior pre-tension lever plate.

Step 5. Remove the Plastic Main Double Gear

- Lift the main double gear to remove it.

REPLACE THE PLASTIC DRIVE TRAIN WITH THE STEEL DRIVE TRAIN

Before continuing check you have all the items in these pictures. One missing part is enough not to be able to complete the procedure.

2/2 . Reassemble the LGX with the Steel Drive Train

Step 1. Install Steel Main Double Gear

- Add the steel main double gear.

- Slide the steel main double gear on the main shaft (thick). Smaller diameter gear up.

- This is the final shape of this step.

Step 2. Install Mid Housing and Posterior Pre-tension Lever Plate

- Add the mid block including mid housing and posterior pre-tension lever plate.

- Position the mid block including mid housing and posterior pre-tension lever plate aligning the mounting holes.

- This is the final shape of this step.

Step 3. Install Metal Drive Gear/Drive Wheels Sets

- Add the metal drive gear/ drive wheels sets.

- Position the steel gears in place. Drive wheels (to grab the filament) up.

- This is the final shape of this step.

Step 4. Install the Drive Shafts

- Add the drive shafts (thin)

- Slide the shafts through the needle bearings inside the drive gear/drive wheel sets.

- This is the final shape of this step.

Step 5. Install the Top Mid Housing

- Add the top mid housing.

- Position the top mid housing. Align it with the top holding hole and main shaft.

- This is the final shape of this step.

Step 6. Install the Anterior Pre-tension Lever Plate

- Add the anterior pre-tension lever plate.

- Position the lever plate to align with the lever shaft and drive shafts.

- This is the final shape of this step.

Step 7. Install the Front Plate

- Add the front plate.

- Place the front cover on top and align the holding holes.

- This is the final shape of this step.

Step 8. Finish the Installation

- Add the two holding screws.

- Insert and tighten the screws in the mounting holes. Don’t force the tightening.

- This is the final shape of this step.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.