Engineer PA-24 Precision Micro Terminal Crimping Pliers

$86.50 AUD inc GST

Out of stock

Engineer PA-24 are an ultra high quality and high precision crimping pliers.

- Specialty of 2.5mm pitch connector contacts of different connector manufacturers, works with JST XH, PH, EH & NH series, Molex Micro-Fit, KK series, etc. AWG #32-#18

- Perfectly crimps triangular insulation barrel (lugs) of DuPont (Servo) connector, Molex C-Grid III, etc. without damaging the insulations.

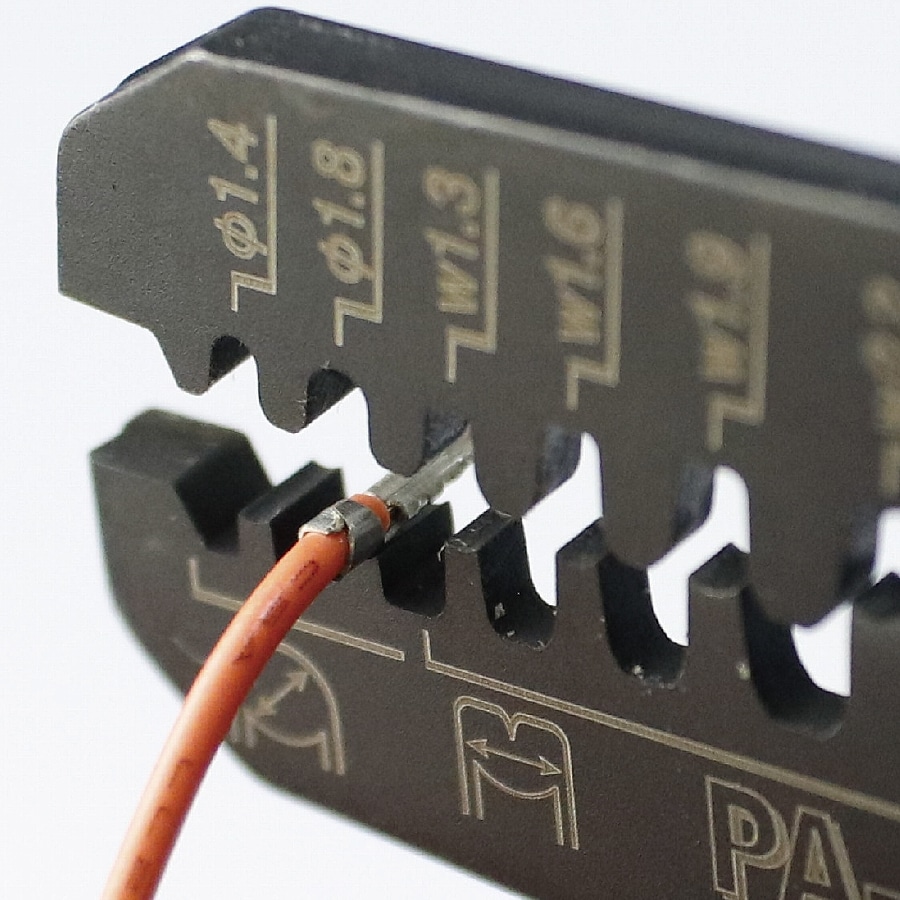

- 6 Crimping Dies (‘m’-shaped crimp: 1.3, 1.6, 1.9 & 2.2mm in width & Round crimp: φ1.4 & φ1.8mm) for open-barrel contacts

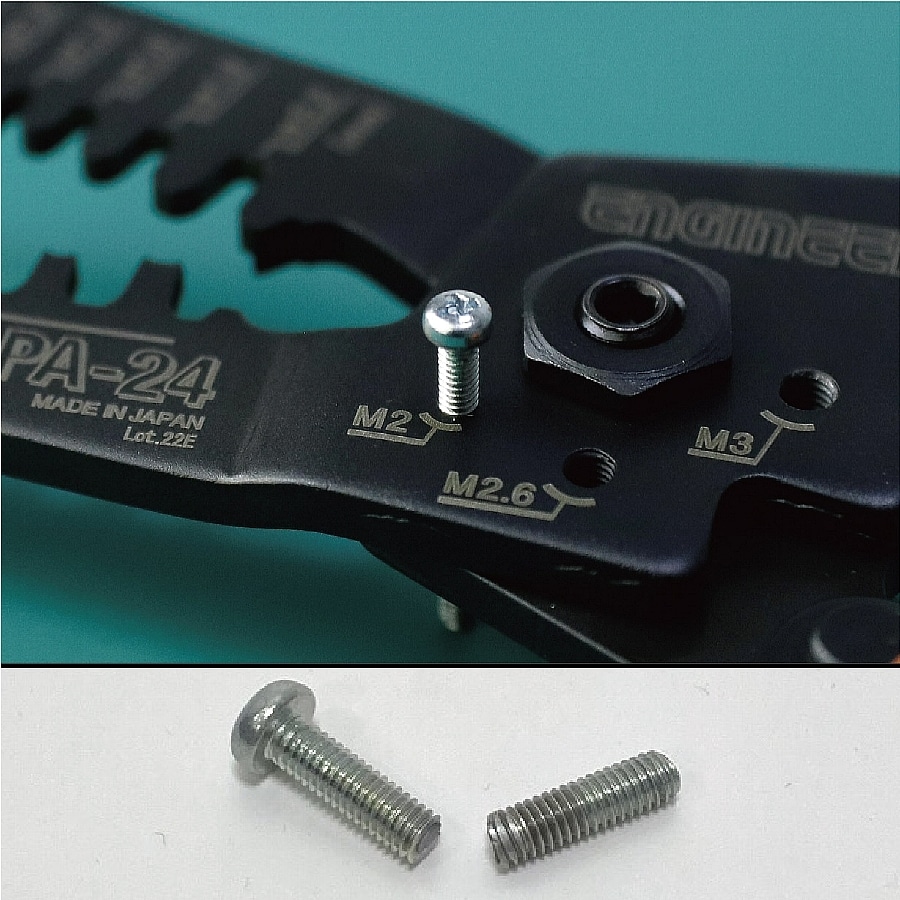

- Built-in screw cutter (M2, M2.6 & M3)

- Tapered and slender jaws, Light weight of 115g only

- Spring loaded (on the back side), with locking latch for easy handling

- Made in Japan

Please see below for further information and technical specifications

Out of stock

Notify when stock available

- Description

- Additional information

- How to select the suitable crimping dies

- Specifications

- Reviews (0)

Description

Crimp Contact Application Chart

Features

M-shaped Dies [1.3, 1.6, 1.9 & 2.2mm in width]

The conductor barrel can be crimped securely.

The insulation barrel can be curled up very tidily.

Round Dies (For DuPont contact etc.) [φ1.4 & φ1.8mm]

Wrap triangular lugs of the barrel around the insulation without damage.

How to select the suitable crimping dies

1. Measure the width of conductor barrel or insulation barrel with a caliper while both barrel lugs are adjusted in parallel.

2. Select the die width that is close to the width of barrel lugs measured. Example: 1.5mm measured –>> Select 1.6mm dies.

3.

Conductor Barrel (Lug) Crimping:

It is better to offset the rearmost edge of conductor barrel (lug) 0.1-0.2 mm from the edge of the upper die to form a bellmouth on the edge of the crimped barrel. (as per the figure on the right)

Insulation Barrel (Lug) Crimping:

Set the insulation barrel (lug) at the center of the upper die in depth to keep the barrel (lug) horizontal when crimping.

Specifications

| Item no. | Dies W(mm) | Dies H(mm) | Dies T(mm) | Wire (AWG) Ref. only |

|---|---|---|---|---|

| PA-24 | 1.3 | 0.5 | 2.2 | #32 to 24 |

| 1.6 | 0.7 | #26 to 24 | ||

| 1.9 | 0.8 | #26 to 22 | ||

| 2.2 | 0.9 | #24 to 18 | ||

| 1.4 diameter | 3.2 | #30 to 28 | ||

| 1.8 diameter | #28 to 24 | |||

Additional information

| Weight | 0.135 kg |

|---|

How to select the suitable crimping dies

1. Measure the width of conductor barrel or insulation barrel with a caliper while both barrel lugs are adjusted in parallel.

2. Select the die width that is close to the width of barrel lugs measured. Example: 1.5mm measured –>> Select 1.6mm dies.

3.

Conductor Barrel (Lug) Crimping :

It is better to offset the rearmost edge of conductor barrel (lug) 0.1-0.2 mm from the edge of the upper die to form a bellmouth on the edge of the crimped barrel. (as per the figure on the right)

Insulation Barrel (Lug) Crimping :

Set the insulation barrel (lug) at the center of the upper die in depth to keep the barrel (lug) horizontal when crimping.

Specifications

| Item no. | O.A. Length | Material | Weight |

|---|---|---|---|

| PA-09 | 175mm | S55C | 145g |

| Item no. | Dies W(mm) | Dies H(mm) | Dies T(mm) | Wires applicable (Ref.) | ||

|---|---|---|---|---|---|---|

| dia. (mm) | mm2 | AWG (wires) | ||||

| PA-09 | 1.0 | 0.50 | 1.7 | 0.20~0.32 | 0.031~0.08 | #32 to 28 |

| 1.4 | 0.55 | 0.32~0.51 | 0.08~0.21 | #28 to 24 | ||

| 1.6 | 0.8 | 2.0 | 0.51~0.64 | 0.21~0.33 | #24 to 22 | |

| 1.9 | 0.9 | 0.51~0.81 | 0.21~0.52 | #24 to 20 | ||

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.